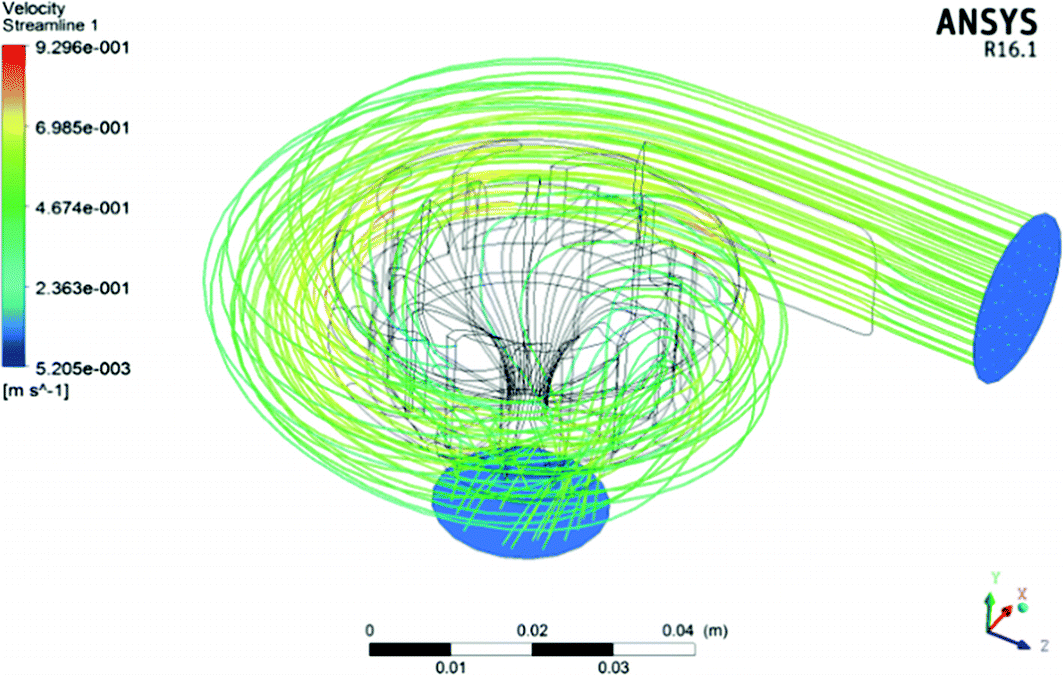

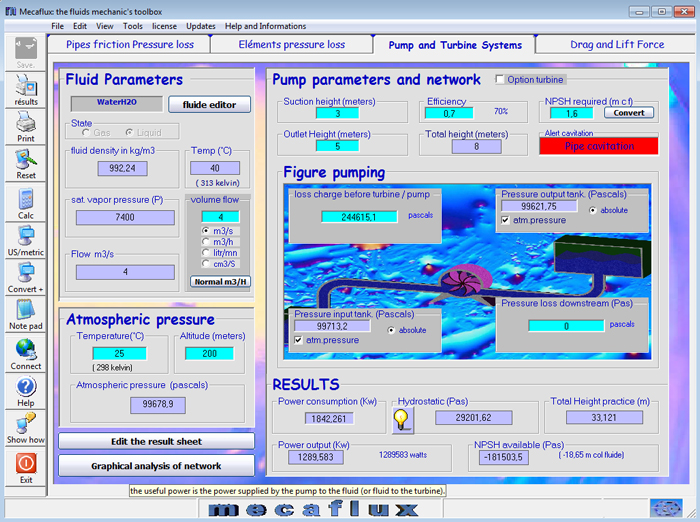

This can be achieved through 3D computational fluid dynamics (CFD) simulation of hydro turbine performance. Instead, you need to know that your products are meeting performance requirements at each step of the development cycle before you ever cut a single prototype. Physical testing is too costly and time consuming for today’s fast-paced market. If you rely primarily on physical tests of prototypes to determine the effectiveness of your designs, then your competition is already winning. But how do you know if the hydro turbines that you engineer are meeting performance and efficiency requirements? As the demand for hydro power increases, so does the demand for ever more efficient hydro turbines. In just about every part of the world, hydro power offers a reliable source for contributing clean and renewable energy to the electricity grid, helping to reduce greenhouse gas emissions.

0 kommentar(er)

0 kommentar(er)